Laser marking is the first time many people have seen the laser processing screen. The rapid scanning of the laser to complete the marking will undoubtedly leave a deep impression on people. It is efficient, accurate, and uses light as the medium for non-contact processing, which perfectly conforms to the public's expectations for future technology. imagine.

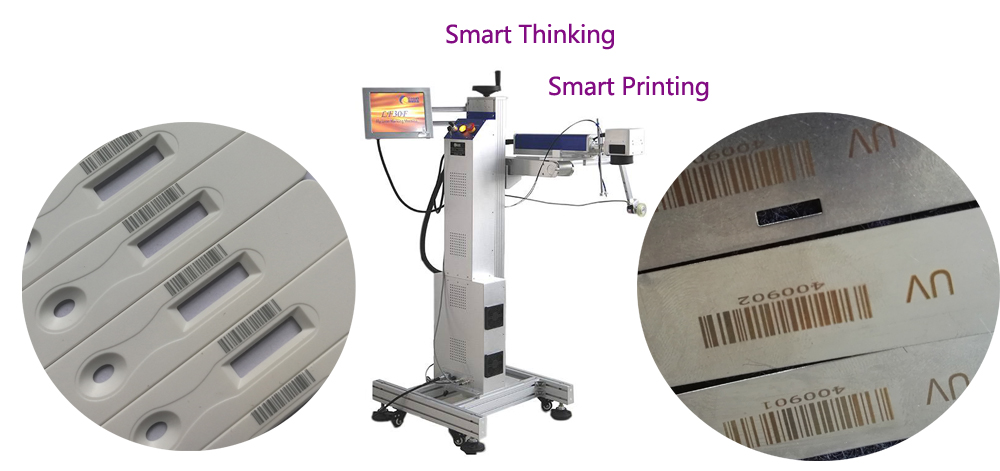

In fact, for practitioners who have actually been exposed to laser marking, this is just an ordinary program that is staged every moment of every day. There are many traces of laser marking on 3C supplies such as chargers and wireless headphones that we often contact around us, and these processing are mainly completed by UV laser printer.

Different from other types of marking equipment, the UV laser marking device adopts the third-order intracavity frequency doubling technology to emit light, which is mainly completed in the form of "cold processing". The ultraviolet laser with a wavelength of 355nm can achieve the effect of etching patterns and characters by breaking the molecular chains of substances.

For thermal processing equipment such as fiber lasers and CO2 lasers, ultraviolet lasers can reduce the thermal deformation of materials to a greater extent, and at the same time, the 355nm ultraviolet light has a very small focusing spot, which is also more advantageous in ultra-fine processing.

The traces of UV laser marking can be seen everywhere in life. Picking up the charger or earphone at hand, we can easily find the processing results of UV marking - most of the text and logo on these 3C accessories are processed by UV laser marking. The text logo on the above will not fade and blur due to time wear and tear. If you touch it with your finger, you will not even feel the slightest bit. The exquisiteness of modern processing technology is fully displayed here.

Of course, UV lasers also have their own limitations, such as working environment, working temperature, and processing materials.

The optimal working temperature of the UV laser marker is 10-35 degrees, and there should not be too much dust in the environment. Although the processing of the UV laser marker will not generate smoke and dust, it is necessary to pay attention to environmental cleaning and equipment maintenance after daily processing.

At the same time, the working life of ultraviolet lasers is not long. The effective light-emitting time of an ultraviolet laser is 12,000 to 14,000 hours. When the average working time and work efficiency are included, it is about 2-3 years, compared to 5-6 years. This is undoubtedly the biggest disadvantage of UV lasers.

Ultraviolet lasers are suitable for processing plastics, glass, flexible PCB boards, metal surface coatings and other materials. Compared with CO2 lasers and fiber lasers, ultraviolet lasers have also been widely used in ultra-fine processing scenarios, such as LCD liquid crystal glass, glassware, silicon wafer microvia, blind via processing, etc.

Fine processing is the advantage of UV laser marking equipment, but to be fine, it is inseparable from the perfect cooperation of laser, motion axis and control system. High-quality lasers, flexible motion axes and intelligent control systems are important options for UV laser marking equipment to be able to work.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 16 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Keywords :

Working video: