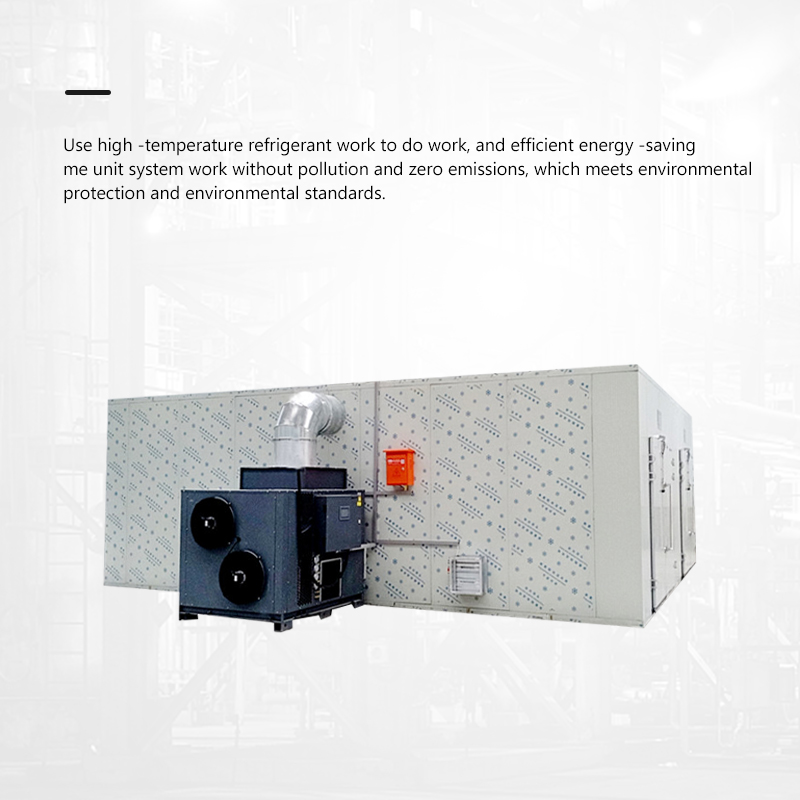

The air energy heat pump drying room is a very common automatic drying equipment among many drying equipment. Its working principle is mainly to use the reverse Carnot cycle principle, use a small amount of electrical energy, use the compressor, evaporate the refrigerant through the expansion valve into gas in the evaporator, and absorb a large amount of heat energy in the air. The gaseous refrigerant is compressed into high-temperature and high-pressure gas by the compressor, and then enters the condenser to release heat, heating the drying medium, In this way, the material is continuously heated until it is dried.

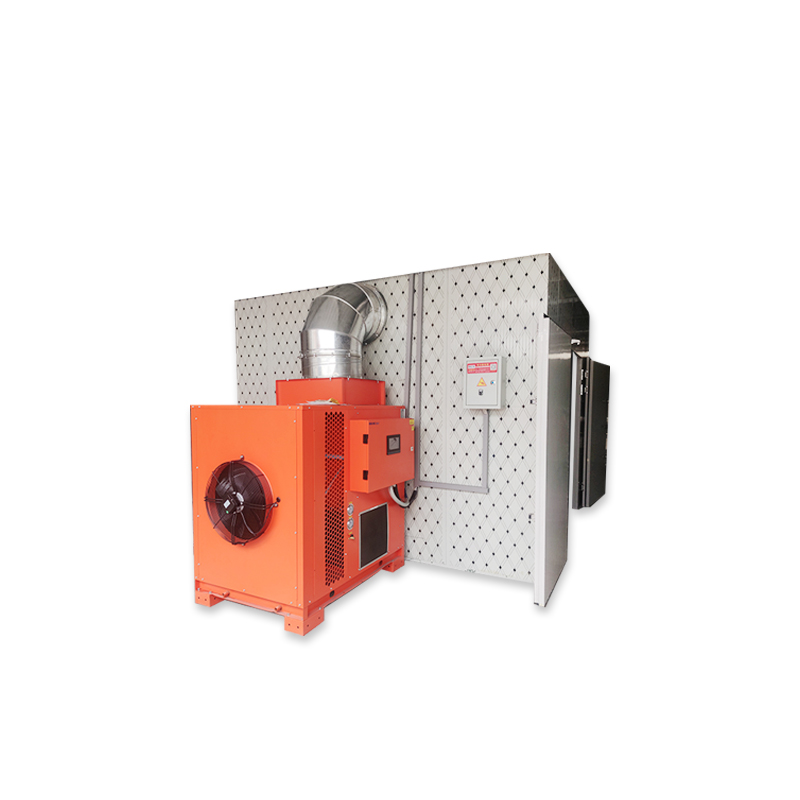

Wide range of applications: air energy heat pump drying room is also nicknamed as "universal dryer", which can dry everything, mainly because its temperature, humidity and other parameters can be precise and controllable, and the equipment can set a variety of different drying process curves according to different material drying process requirements to achieve high-quality drying effect. And with its 24-hour continuous operation characteristics, it is more suitable for mass production in the factory, which can further reduce the average production cost, so that more and more material drying manufacturers choose to use air energy drying room for material drying.

Energy conservation and environmental protection. Especially under the situation that the domestic environmental pressure is growing and the government's management on environmental protection is growing, the production mode with environment-friendly, zero pollution, clean working environment and low noise pollution are also important reasons why more and more customers choose air drying rooms.

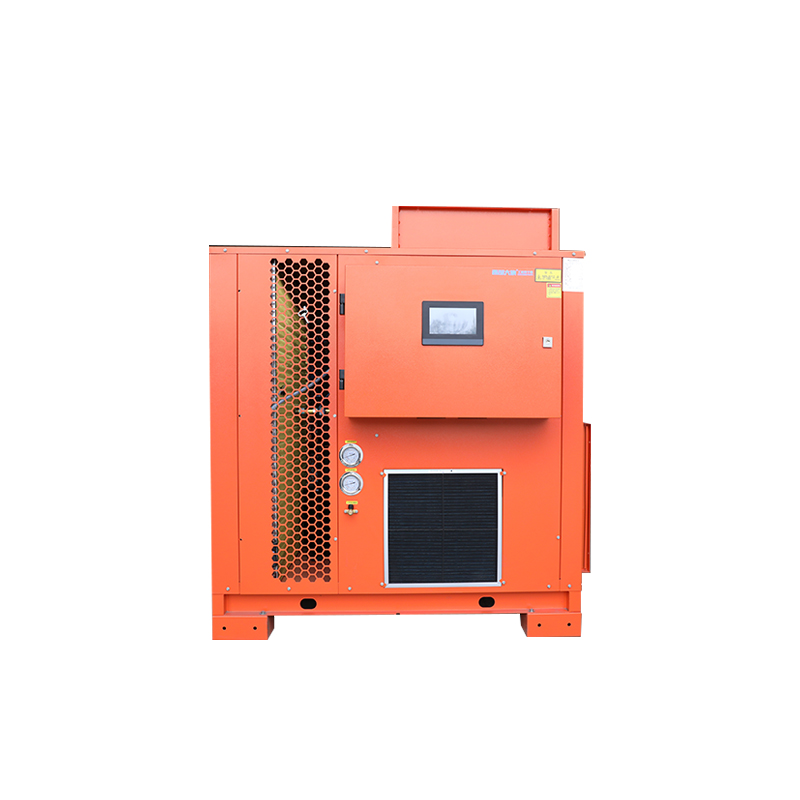

Precise temperature control: The air energy heat pump dryer organically integrates the traditional drying process with the automation technology, fully absorbs the advantages of the traditional hot air drying process, and realizes high-quality drying operation. As the main body of the air energy drying room is a closed drying room, compared with the traditional mesh belt dryer, the air energy drying room can more accurately control the temperature, humidity and other drying parameters in the drying room, so that the dried materials have good color, less deformation, less nutrient loss, no pollution, good quality, good rehydration, and ensure the drying quality of materials. And because the materials are in the closed space of the drying room, and the drying with pure hot air will not have any contact with the outside world, it will be more hygienic than the traditional drying method, which can make the dried materials fully meet the food and drug health requirements.

Intelligent operation is simple: PLC touch screen is widely used in the air energy drying room, which is simple and easy to learn. After being trained and familiar with, Xiaobai can immediately start to operate. On the one hand, because it is equipped with an automatic intelligent operating system, the equipment can automatically dry and run after the specific production process just needs to set the parameters in advance, which can save labor costs without the need for special personnel. On the other hand, with the continuous improvement of air energy drying technology, the drying system can work more reliably and stably, making the maintenance more simple and convenient, and greatly reducing the daily maintenance costs.

Sichuan Zhongzhi Qiyun General Equipment Co., Ltd. is a key manufacturer of general equipment in Deyang City, which has been approved by the Municipal Development and Reform Commission and approved by the municipal environmental protection, safety supervision, fire protection, energy saving and other departments. It is a director unit of the People's Enterprise Federation; it has dozens of invention patents and is a national high-tech enterprise and a technology-based small and medium-sized enterprise. The production base is located in the National Economic Development Zone of Deyang City, 2 kilometers away from the Deyang South Exit of Chengmian Expressway. The project covers a total area of more than 20 acres, with a construction area of 11,000 square meters in the first phase. It has hundreds of processing tools for turning, milling, planing, riveting, welding, shearing and folding, and hundreds of skilled workers.

CIIC integrates scientific research, development, production and manufacturing into one. It owns two industrial brands, "Western Banner" and "Chuanyao". It has three subordinate departments of drying, heat energy, and dust removal and four subsidiaries. With modern business philosophy It has gathered a large number of industry elites with its management ideas, and has 11 professor-level senior engineers and engineering technicians who have been engaged in the research, development, design and manufacture of drying and related equipment for more than ten years. At present, there are three series and nearly 400 specifications of drying, dust removal and heat exchange equipment, which are widely used in chemical industry, traditional Chinese medicine, food, light industry, metallurgy, agricultural product processing, environmental management and other industries.

Over the past ten years since the establishment of the company, Cowin people have been committed to developing new technologies and new products to meet customer needs, making the products increasingly perfect, and exported to domestic provinces and cities and more than a dozen foreign countries; through the establishment of an efficient after-sales service system, the service has been greatly improved. quality, and has gradually become a model enterprise that the same industry is eager to emulate. Warmly welcome more friends to visit our factory. We firmly believe that technology creates brand and integrity creates brilliance. We will continue to repay the society with better products and services.

Contact Person:Lin Shuangqi

Email:5720067@qq.com linshaugnqi@gmail.com