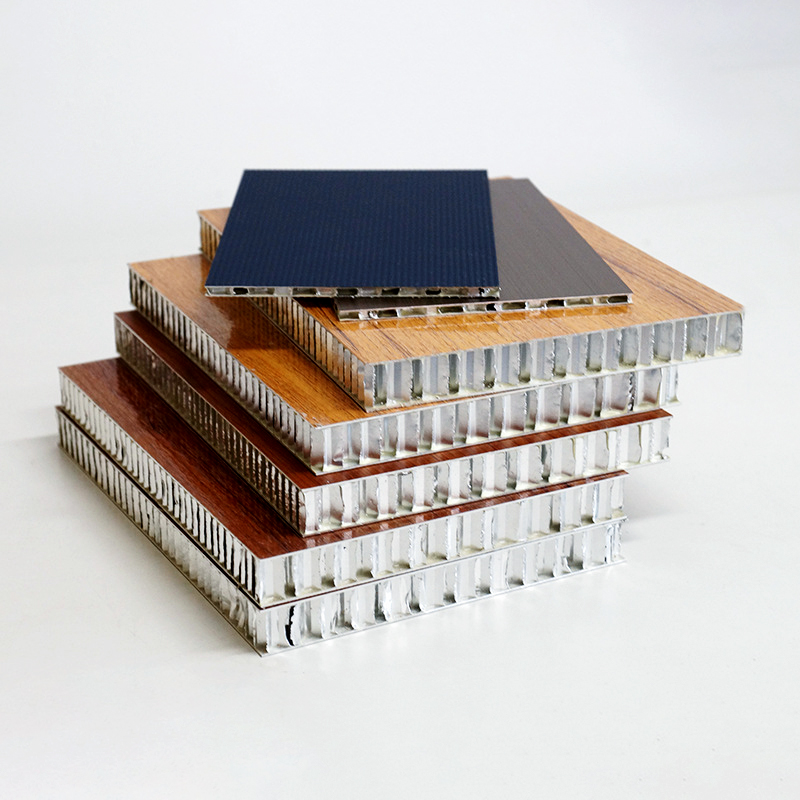

Aluminum honeycomb panel, applicable to civil buildings, vehicle and ship decoration, etc. It is the application of aviation and aerospace materials in civil construction. The whole processing process is completed in a modern chemical plant. The hot pressing technology is adopted. Because of the high heat conduction value between the aluminum skin and the honeycomb, the thermal expansion and cold contraction of the inner and outer aluminum skin are synchronized; There are small holes on the honeycomb aluminum skin, so that the gas in the plate can flow freely; The sliding mounting buckle system will not cause structural deformation during thermal expansion and cold contraction. The panel mainly uses high-quality 3003H24 alloy aluminum plate or 5052AH14 high manganese alloy aluminum plate as the base material. The panel thickness is 0.8~1.5mm fluorocarbon roller coating plate or color light resistant baking paint. The color light resistant baking paint is stronger than PVDF in terms of scratch resistance, acid rain corrosion discoloration resistance and self-cleaning. The thickness of the bottom plate is 0.6~1.0mm, and the total thickness is 25mm.

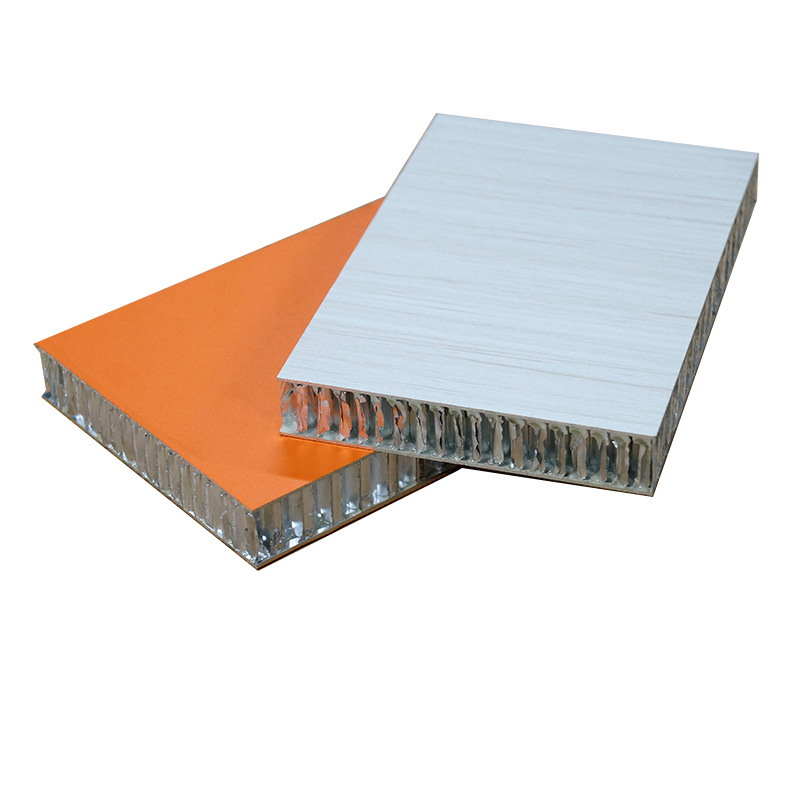

The core material is hexagonal 3003 aluminum honeycomb core. The thickness of aluminum foil is 0.04~0.06mm, and the side length is 5~6mm. The front and back skins are formed by rolling forming technology. The full-automatic machine equipment folds the edges, and the front and back skins are tightly engaged at the installation edge. The whole processing process is completed in a modern chemical plant. The hot pressing technology is adopted. Because of the high heat conduction value between the aluminum skin and the honeycomb, the thermal expansion and cold contraction of the inner and outer aluminum skin are synchronized; There are small holes on the honeycomb aluminum skin, so that the gas in the plate can flow freely; The sliding mounting buckle system will not cause structural deformation during thermal expansion and cold contraction, so it can ensure extremely high flatness Adhesive: two-component polyurethane high temperature curing adhesive, which is compounded by automatic honeycomb panel composite production equipment under pressure and high temperature, overcomes the brittleness problem of the previous honeycomb panel bonding layer. The inner layer is a specially made hexagonal aluminum honeycomb, which is composed of aluminum alloy with a hardness of H19. As a core plate adhered to the sandwich structure, it bears tangential pressure. These closely spaced honeycombs are like many small I-beams, which can bear the pressure from the panel direction in a decentralized manner, so that the plate is evenly stressed, and ensure that the panel can still maintain a high flatness in a large area.

The installation shall be carried out on both sides without mechanical damage. The sliding mounting buckle system allows thermal expansion and cold contraction, and the anti sliding buckle at the bottom of the plate can control the expansion direction of the plate. The 25MM hidden glue seam system is beautiful and has self-cleaning function After fabrication, the box honeycomb panel, the inner and outer panels and the honeycomb structure form a whole. In addition, the hollow honeycomb can greatly reduce the thermal expansion of the panel.

Honeycomb materials have excellent properties such as high wind pressure resistance, shock absorption, sound insulation, heat preservation, flame retardancy and high specific strength. In the 1960s, the honeycomb technology has been used in various fields of civil industry in foreign countries and has developed rapidly. In China, the honeycomb technology has been applied in various fields of civil industry. Aluminum honeycomb panel curtain wall has been widely used in high-rise building exterior wall decoration because of its light weight, high strength, high stiffness and many other advantages. The total thickness is 15mm. The aluminum honeycomb panel with 1.0mm thick panel and bottom plate is only 6Kg/㎡. The weight of honeycomb panel with the same stiffness is only 1/5 of that of aluminum veneer and 1/10 of that of steel plate. The interconnected aluminum honeycomb core is just like countless I-beams. The core layer is distributed and fixed in the whole panel surface, which makes the panel more stable. Its wind pressure resistance performance is greatly superior to that of aluminum plastic panel and aluminum veneer. It is not easy to deform and has good flatness, even though the partition size of honeycomb panel is large. It can also achieve extremely high flatness, and is the first choice of lightweight materials in the construction industry.

Aluminum honeycomb panel, applicable to civil buildings, vehicle and ship decoration, etc. It is the application of aviation and aerospace materials in civil construction. The whole processing process is completed in a modern chemical plant. The hot pressing technology is adopted. Because of the high heat conduction value between the aluminum skin and the honeycomb, the thermal expansion and cold contraction of the inner and outer aluminum skin are synchronized; There are small holes on the honeycomb aluminum skin, so that the gas in the plate can flow freely; The sliding mounting buckle system will not cause structural deformation during thermal expansion and cold contraction.

Seivu enterprises was founded in 2009.Chongaing Seivu New Wall Material Co.LtdLocated in Chongaing Nanchuan Industrial Park Chongqing Seiyucurtain wall aluminum manufacturingCo.Ltd located in Chongqing Jiulongpo Xipeng Aluminum Industrial Park, close to the Southwest Aluminum(Group)aluminum processing plants,logistics,transportation are very convenient.As an enterprise operating on shareholding system,Seiyu is committed to the research and development,design,manufacture,sale and installation of the aluminum metal curtain wall decorative sheet products and composite board which combines insulation and decoration function.

The company gathered a group of technical elitesproduction backbones,management talentswho engaged in the construction of curtain wall aluminum veneer industry more than 20 yearsThey possess of high professional, pursuit of excellence, adhere to the core concept that quality is life,firmly establish the real Seiyu Brand values.Seiyu keeps a long-term friendly cooperation in the aluminum deep processing industry with the aluminum. Southwest Aluminum(Group)units:industrial companies.The win-win cooperation creates West Aluminum"brand aluminum veneer. products are widely used in the national special heavy project , which not only makes the image of the Seiyu famous all over the world,but also makes the company getadvanced technology, excellent quality and production management experience, and create high-quality brand"SEIYU". With the help of professional talents and cutting-edge technology,the reserves of the successful performance makes Seiyu become the leader of aluminum veneer industry.

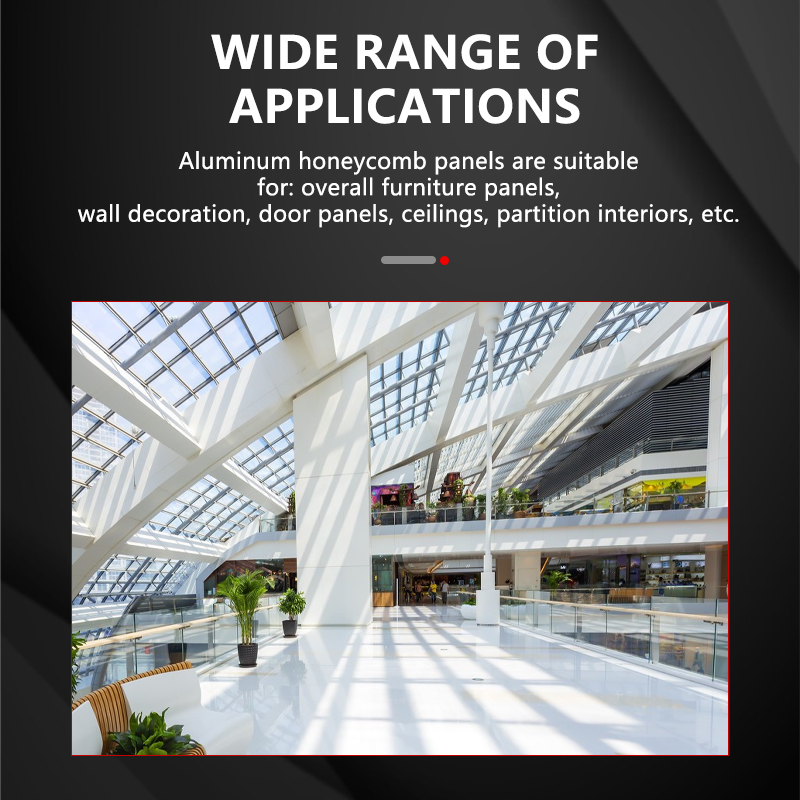

The company has beautiful environment, bright and bright factory buildings and office buildings. It has excellent metal curtain wall forming sheet metal processing equipment.The special CNC equipment industry has a leading and wide range, and has the most advanced modern high-speed fiber laser cutting machine, and sheet metal processing is handy. Carbon steel, stainless steel. aluminum alloy, brass and other medium and thick materialscarved flower shapeversatile and versatile with the heart strain. The spraying system adopts the Japanese lIAnd full automatic electrostatic spray gun and the super large spray paint production line (the single piece of sheet metal processing spray finished 2200*12000 mm).products such as curtain wall aluminum veneer, perforated carved aluminum plateimitation stone wood orain aluminum plate. modelina smalloox aluminum plate. honevcomb porcelain aluminum plate, single and double curved aluminum platealuminum magnesium manganese roof panel, all kinds of decorative aluminum. eneray saving decorative single integrated board are widelyused in buildina Hiah-speed rai station. Sports venues. Theater museums, convention centers, transportation hubscommercial centersschool hospitalsstar hotels, shopping malls, shopping malls and so on. They are also widely used in buildina buildinasAdministrative office buildinas.hiahway tol stations. The old house municipal transformation, advertising signs, public building complex facilities such as indoor and outdoor decoration. First-class technology and equipment, first-class materials to create exauisite products. Architecture is the eternal art. The use of innovative excellencethe achievements of the beauty of excellence. Exquisite products are also the choices mastersTo create value for customers is the law of companies survival. Seiyu with real products, first-class qualityfirst-class service, first-class reputationhoping to cooperate with you sincerely. to create brilliant.

Na Chen

nachen5579@gmail.com

tantongyou@163.com

2431964588@qq.com