The intaglio printing machine is mainly used in food packaging, drug packaging, daily chemical packaging, PVC label printing and other plastic film types1, printing valuable securities such as RMB securities and stamps, 2, printing cigarette boxes, wine boxes and other relatively high-end printing, 3, the drying method of intaglio printing is mainly volatile drying, film printing with large printing volume, such as instant noodles, milk boxes and so on. Therefore, intaglio printing is the best choice, and the printing volume is generally large. Gravure printing machine is the most common one on the market. The intaglio printing machine often uses a physical printing method when printing, that is, the printing ink in the image part is completely a kind of stacking load, and the non image part is concave or convex, so it cannot touch the printing ink and leave it blank. Therefore, the printing ink in the image part is transferred to the printed material, which is only a physical and mechanical function. The thickness of printing is related to the depth of the concave, which is thick and light. The printed lines are convex. Coins, stamps, securities, etc. are all printed by intaglio printing, which is suitable for the printing of plastic film and silk, but the cost of this printing process is often high.

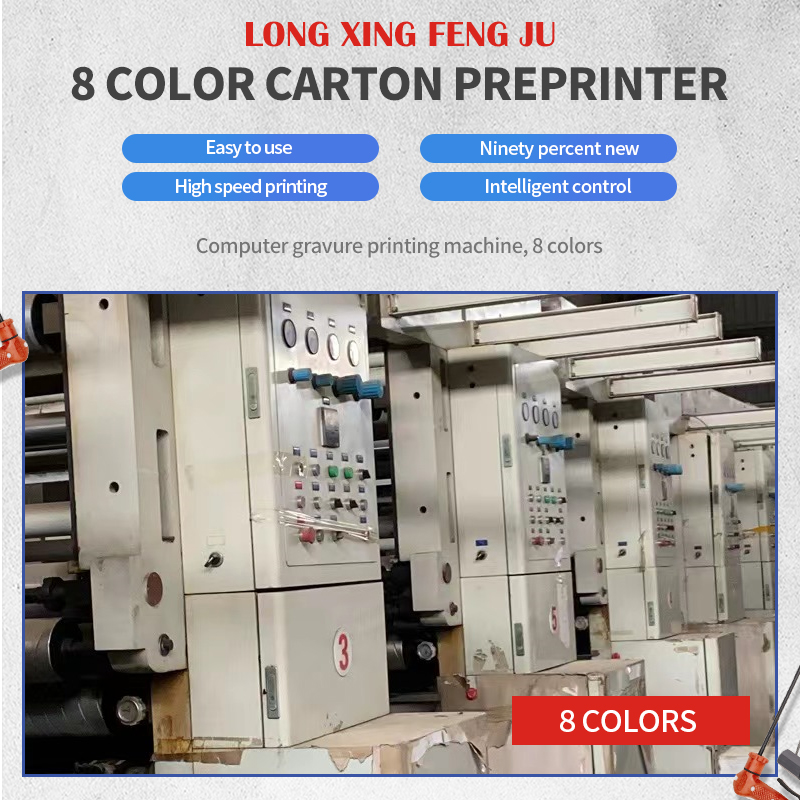

Features of Shaanxi Beiren computer gravure printing machine:

1. Unwinding part: shaftless roll loading, which can adapt to different paper cores, and can be replaced quickly. High speed non-stop material change, saving time, improving efficiency, zero speed difference roll change, stable tension, and low scrap rate.

2. Printing section: the shaftless version can be quickly replaced, and the positioning is accurate. The initial version alignment system can quickly enter the register printing. The three-way scraper adjustment can create the best scraper position angle.

3. Drying section: the secondary return air adopts energy saving, single group automatic constant temperature control, which is favorable for printing of various colors. High wind speed and high flow can create a drying method of low temperature and high wind speed. The negative pressure design in the whole box prevents hot air from flowing out.

4. Cooling part: obvious cooling effect, self overflow type for reflux, no need for large water pressure, no need for rotary joint, large wrap angle of water cooling roll, long contact material, obvious cooling effect, flexible operation and convenient maintenance of rolling bearing.

5. Winding part: shaft less coil loading, fast replacement, high-speed non-stop coil changing, saving time, improving efficiency, zero speed difference coil changing, stable tension, low scrap rate, consistent tension inside and outside the winding, no vegetable core phenomenon.

6. Rack and feeding part: the overall wallboard is free of secondary internal stress, with high stability. It is processed by imported processing center with high precision. The positioning holes are processed first to ensure accurate positioning of each group, smooth layout of guide rollers, and stable operation of coiled materials.

7. Tension control: the four section tension of the whole machine is fully closed loop controlled, with high tension control accuracy, and the speed of rise and fall does not affect the tension.

8. Lighting system: safety explosion-proof system based on people first.

9. Electrostatic elimination system

Sichuan Longxing Fengju Electromechanical Equipment Co., Ltd. was established on December 14, 2016, and successfully developed mechanical automation control software and sheet metal processing production line with Tsinghua University, the Ministry of Aerospace Industry and other units. It is committed to building the largest and most professional plastic intaglio computer printing machine, compound machine, slitter, etc. in China. It has a huge service network, and its high coverage and efficient services have been recognized by many companies and institutions. The quality policy is: pioneering and innovation, leading the trend, quality assurance, and brand building, which is to create a life and provide customers with a continuous stream of high-quality products. Adhering to the business philosophy of "quality assurance, customer first", our company has established a good reputation in the industry with advanced production technology, perfect quality monitoring system, strict quality inspection system, and excellent after-sales service. We will provide you with safe, economical and professional services in the most professional spirit.

Wen Kai Long

1025391189@qq.com