Most of the finished rolled rebars are used in large-scale water conservancy projects, continuous beams and large-scale frame structures in industrial and civil buildings, transportation, railway large and medium-span bridges, nuclear power plants and ground anchor projects. It has the advantages of simple linking and anchoring, good adhesion, safe and reliable tensioning and anchoring, convenient construction, etc., and saves steel bars and reduces the area and weight of components.

The appearance dimensions of the finished threaded steel bars conform to the requirements of the Highway Planning and Design Institute of the Transportation Department for the dimensions of the prestressed high-strength finish rolled threaded coarse steel bars. The regular size is 9 meters and 12 meters in length, and the size can also be made according to customer needs.

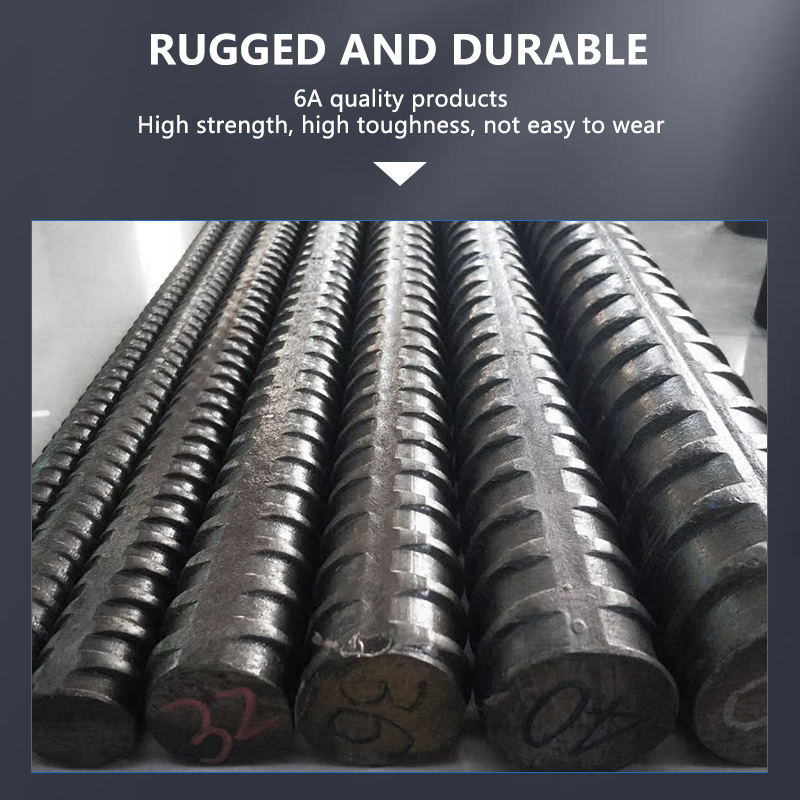

Rebar for prestressed concrete (also known as finish-rolled rebar, hereinafter referred to as rebar) is a hot-rolled straight bar with discontinuous external threads. The rebar is screwed with a connector with internal thread for connection or screwed on a threaded nut for anchoring at any section. The strength grades of steel bars are PSB785, PSB830, PSB930, and PSB1080, which are divided into grades by yield strength, and their code is “PSB” plus the minimum specified yield strength. P, S, and B are the first English letters of Prestressing, Screw, and Bars, respectively. For example: PSB830 represents a steel bar with a minimum yield strength of 830MPa.

Finish-rolled rebar is a special-shaped straight bar with discontinuous external threads at any cross-section.

All can be connected or anchored with connectors or anchors with internal threads.

This product is widely used in large bridges/slope protection projects/foundation anchoring/bridge suspension construction projects. It has the advantages of simple connection/anchorage/high safety/convenient construction.

Vanadium-containing new grade III rebar (20MnSiV, 400Mpa) is added with vanadium, niobium, titanium and other alloys in the production process. Compared with ordinary grade II rebar, the

It has the advantages of high strength, good toughness, good welding performance and shock resistance. In the construction market of developed countries such as Europe, grade III rebar accounts for 80% of the total rebar. In 1995 in my country, the former Ministry of Metallurgy and the Ministry of Construction jointly issued a document to promote the application, and the Ministry of Construction included the technical conditions of the new grade III threaded steel bar into the national standard GBJ10-89 "Code for Design of Concrete Structures"

Each set of JLM type finish-rolled rebar anchors includes nuts and backing plates, which can anchor φ25, φ28, φ32 and other high-strength finish-rolled rebars. Large building roof trusses, in ground anchors for slope reinforcement.

Chengdu Yuanzhijiu Trading Co., Ltd. is located at No. 16, Building 16, Liangli Steel City, Jinniu District, Chengdu. Rubber bearings, expansion joints, spacers, prestressed jacks, tensioning machines and other supporting entities. Our company has long-term supply finish-rolled threaded steel anchor nuts, backing plates, finish-rolled threaded steel connectors, and all products meet industry standards "Anchorages, fixtures and connectors for prestressed tendons" GB/T 143710-2007 and other relevant regulations. The company's products are widely used in highways, railways, hydropower, housing construction foundation pits, slope support and other fields.

In line with the business philosophy of dedication, integrity, pragmatism and innovation, the company creates high-quality projects for various bridges and geotechnical companies. Taking worry-free quality as our responsibility, we look forward to closer contact with our partners, and we look forward to new and old friends visiting us for inquiries.

Ma Mingson

910539686@qq.com