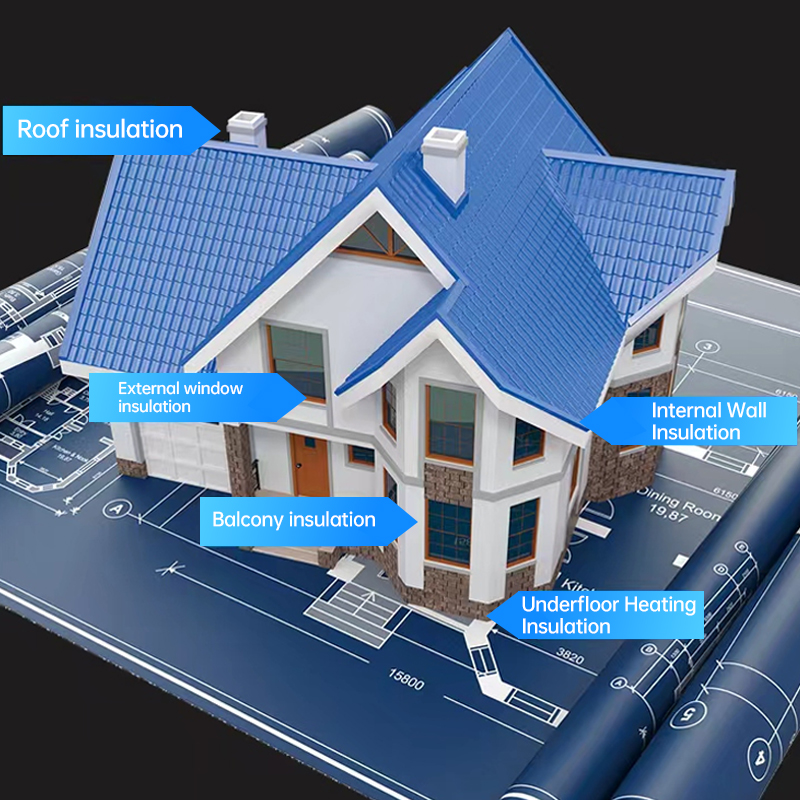

It is mainly used for building wall, roof insulation, composite board insulation, thermal insulation of refrigerators, air conditioners, vehicles, ships, floor heating, decoration carving, etc.

1. If EPS foam board is used in external wall thermal insulation system, its apparent density must meet the requirements of JG149-2003 External Thermal Insulation System with Expanded Polystyrene Board Thin Plastering, that is, the apparent density is 18~22kg/m3.

2. Maintain the main layout of the building and extend the life of the building. Because external insulation is to place the insulation layer outside the layout, it reduces the stress of layout deformation caused by temperature change, and reduces the corrosion of harmful substances in the air and ultraviolet rays on the layout.

3. It is good for keeping the room temperature stable. The external wall insulation is selected because the wall heat storage can be largely arranged inside the wall, which is good for keeping the room temperature stable.

4. Polystyrene material is widely used in the construction and packaging industry because of its light weight, earthquake resistance, fall resistance, heat insulation, sound absorption, heat preservation, self extinguishing, environmental protection, anti-aging, low cost, easy construction and other advantages.

5. When the foaming EPS beads are heated to above 90 ℃, the beads will soften, and the vaporization of the foaming agent can make the EPS beads expand 40-80 times.

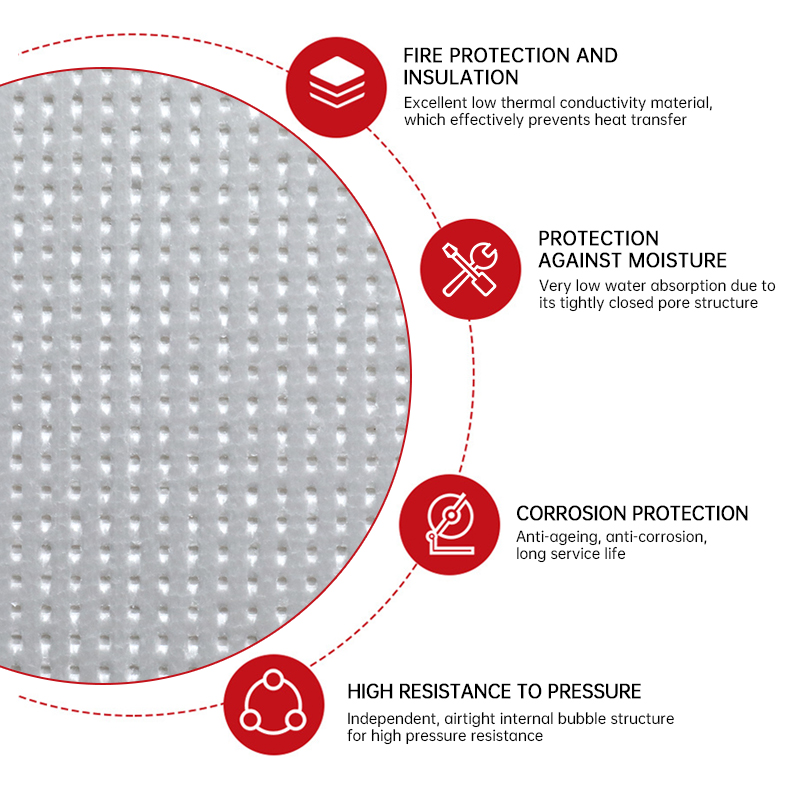

1. Excellent thermal insulation

It has the characteristics of high thermal resistance, low linearity, and low expansion ratio. Its structure has a closed cell rate of more than 99%, forming a vacuum layer to avoid air flow and heat dissipation, and ensure the durability and stability of its thermal insulation performance. Compared with the 80% closed cell rate of foaming polyurethane, it has obvious advantages. Practice has proved that the thermal insulation effect of 20mm thick XPS extruded insulation board is equivalent to 50mm thick foamed polystyrene and 120mm thick cement perlite. Therefore, this material is the best choice for building insulation at present.

2. Excellent high strength compression resistance

Due to the special structure of XPS board, its compressive strength is extremely high and its impact resistance is extremely strong. According to the different models and thicknesses of XPS, its compressive strength can reach 150~500Kpa or more, and can withstand the ground load of various systems. It is widely used in geothermal engineering, highways, airport runways, square grounds, large cold storage, interior decoration and thermal insulation and other fields.

3. High quality hydrophobicity and moisture resistance

Water absorption is an important parameter to measure thermal insulation materials. After absorbing water, the thermal insulation performance of the thermal insulation material decreases. At low temperatures, the water inhaled is easy to freeze, which destroys the structure of the thermal insulation material, thus reducing the compression resistance and thermal insulation performance of the plate. Because the polystyrene molecular structure itself does not absorb water, the plate molecular structure is stable and has no gaps, which solves the problems of other materials such as water leakage, penetration, frosting and condensation.

4. Light and easy to use

The completely closed cell foaming chemical structure and honeycomb like physical structure of XPS board make it light and high-strength, easy to cut, transport, not easy to damage, and easy to install.

5. Good stability and corrosion resistance

During a long period of use, it does not age, decompose, or produce harmful substances. Its chemical properties are extremely stable, and it will not degrade due to water absorption and corrosion, which will reduce its performance. It can still maintain its superior performance in high temperature environments. According to relevant information, XPS extruded temperature protection plate can maintain excellent performance even after 30 to 40 years of use, and it will not decompose or mildew, and there is no volatilization of toxic substances.

6. Product environmental performance

The XPS board has been tested by the relevant national departments to be chemically stable, non volatile and harmless to human health. The raw materials used for production are environment-friendly and do not cause any industrial pollution. This product is an environment-friendly building material.

Chengdu Yukang Feiyang Thermal Insulation Materials Co., Ltd. is a modern enterprise producing energy-saving and environment-friendly building materials such as thermal insulation materials, fire-resistant and fireproof materials, sound absorption and noise elimination materials.

The main products include XPS extruded board, glass wool products, fire and thermal insulation rock wool products, EPS polystyrene board, A-grade polyphenylene board (permeable, granular), aluminum silicate ceramic products, rubber sponge products, polyurethane, high pressure polyethylene (PEF), asbestos free microporous calcium silicate, foam glass, foam cement insulation board, vitrified beads and inorganic vitrified beads, expanded perlite, perlite board, etc.

The company integrates scientific and technological development, production, manufacturing and sales. At the same time, in order to transform the first-class technology into first-class products, the company implements scientific management on all equipment and production technologies, and tracks and monitors the quality and technology of production processes throughout the city.

The company adheres to the business tenet of "honesty". With the increasing demand of domestic and foreign markets, we will further expand the production and sales scale on the premise of improving quality and increasing varieties. No matter now or in the future, we will continue to serve our customers, and we sincerely welcome new and old customers to visit and guide us.

Fu Honghui

609816814@qq.com