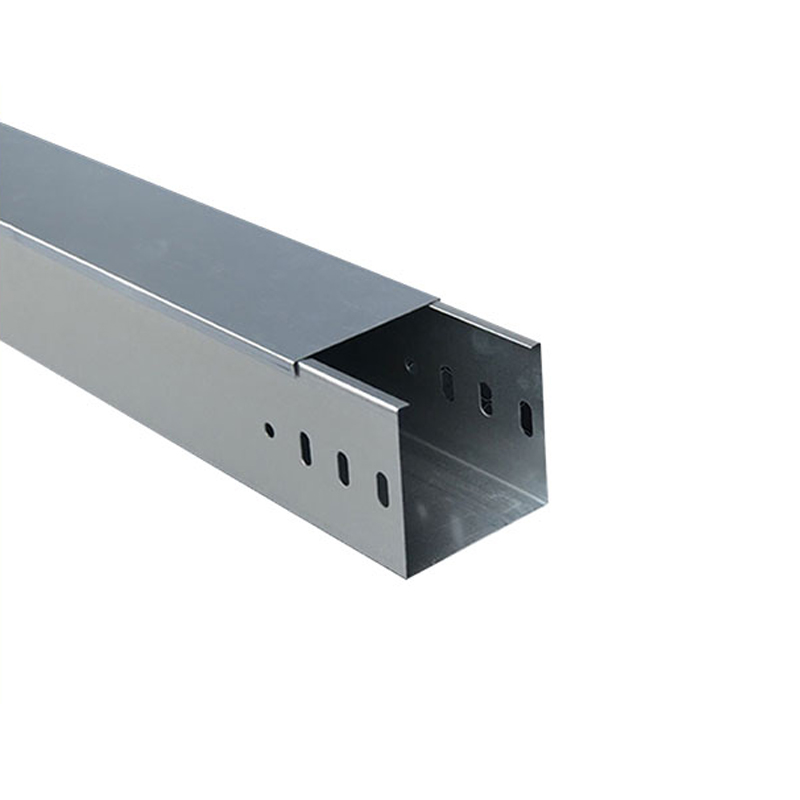

Galvanized trough cable bridge is a trough component made of the whole steel plate. The difference between it and tray in concept is that the ratio of height and width is different, the tray is shallow and wide, and the trough cable bridge has a certain depth and sealing property. Galvanized trough cable tray is a fully enclosed cable tray, which is most suitable for laying computer cables, communication cables, thermocouple cables and other control cables of highly sensitive systems. It has a good effect on controlling cable shielding interference and protecting cable in heavy corrosive environment.

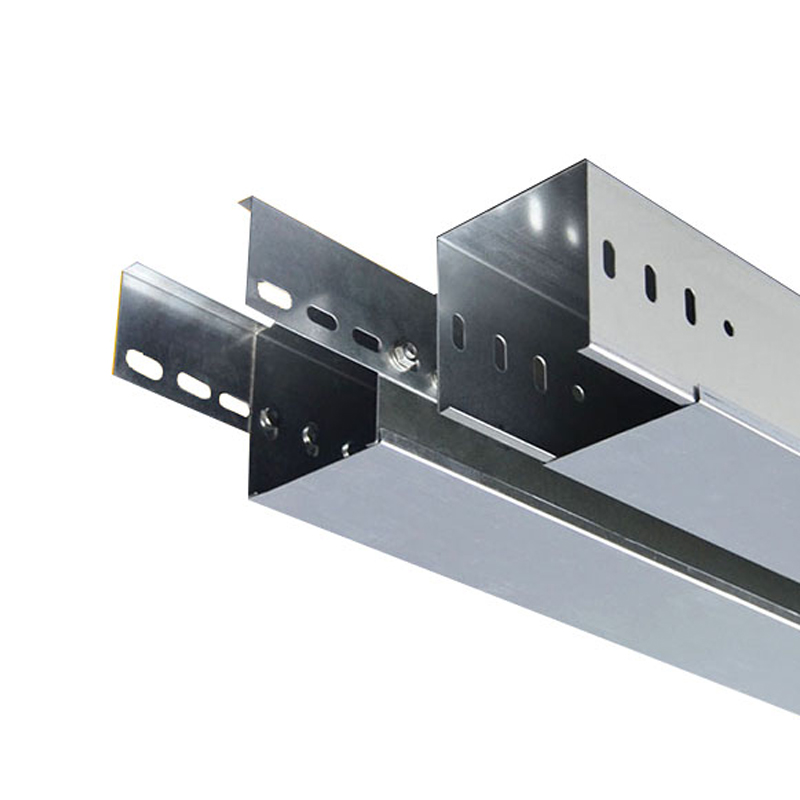

Grounding points:

1. The bridge system should have reliable electrical connection and grounding (only for the metal bridge).

2. The following requirements should be met when the bridge system is allowed to form the grounding circuit. The connection resistance between the ends of the bridge should be no more than 0.00033 ohms, and the grounding hole should be cleared of the insulation coating. In the neutral direct grounding system of 1KV and below, the grounding of the electric equipment is connected with the neutral grounding of the system. When the power supply is cut off, the metal cross-sectional area of the prefect direction of the bridge should not be less than the specified value.

3. When the grounding trunk line is laid along the full length of the bridge, each section (including the non-linear section) of the bridge should have at least one reliable connection with the grounding trunk line.

4. For vibration sites, spring rings should be installed at the connection of the grounding part.

Features:

1, simple structure, beautiful shape.

2. Easy and flexible installation. It is most suitable for indoor and outdoor overhead laying power cables, control cables and lighting wiring, etc. It is also suitable for laying all kinds of pipelines; In addition, it is also suitable for the reconstruction project of road and bridge with large span.

3, good heat dissipation performance, low temperature: its surface treatment is divided into electrostatic powder spraying and hot dip zinc two ways, hot dip zinc refers to the workpiece into 600°C melting zinc liquid and hold for a certain time can be put out.

4. Strong corrosion resistance: the corrosion resistance of the trough bridge after spraying is many times stronger than that of the general rigid metal bridge (such as steel bridge).

Guizhou Feiyun cable tray Co., Ltd. is a well-known enterprise specializing in the production of cable trays in China. After years of development and advanced manufacturing equipment, employees have received professional technical training and produced each product according to industry standards. This enterprise specializes in the production of a series of junction cable trays. Its main products include: trough type, tray type, cascade type, combined type and long-span steel cable trays and organic flame-retardant, bus duct, inorganic fire-proof series cable trays. There are three kinds of surface anti-corrosion treatments: painting, static electricity, plastic spraying and electroplating. It is suitable for laying all kinds of cables and pipelines. It can be used for metallurgy, electric power, petrochemical, textile, electromechanical and other industrial and mining enterprises and indoor and outdoor places of hotel buildings, overhead cable laying or cable trench, laying in tunnels, long-span overpasses, etc. Since its inception, the company has continued to develop, market-oriented, quality for survival, excellence, establish a brand, and work hand in hand with you with sincere enthusiasm to explore the future, in exchange for your 100% satisfaction with perfect services.

Contact Person:Qiu Rensong

Email:254679560@qq.com