Robot application scope

1、Industrial production field

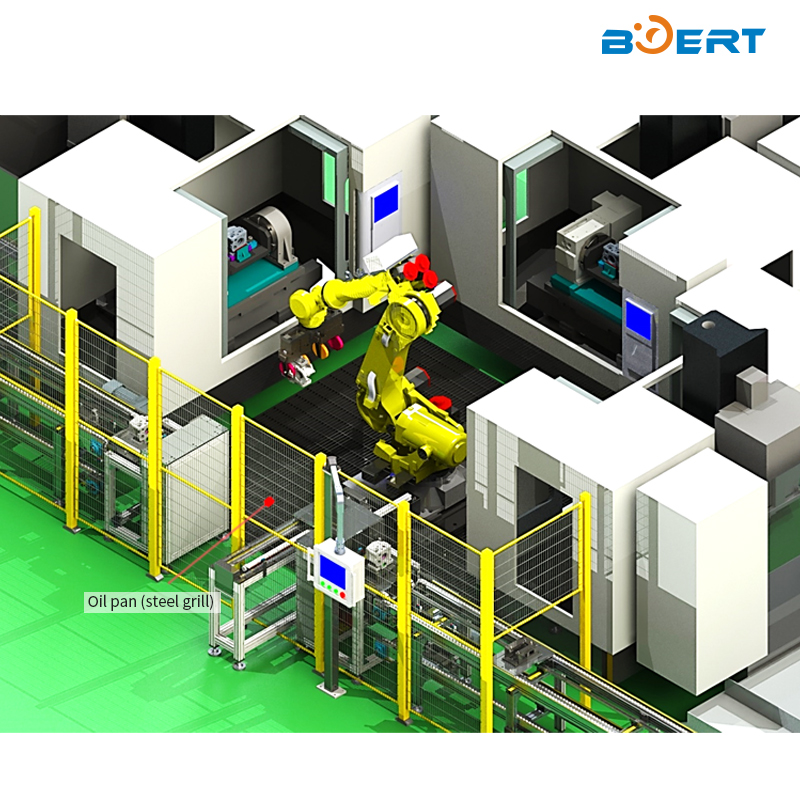

At present, a large number of robots are already involved in the production process in the industrial production field, for example, a large number of industrial robots are used in the automobile manufacturing field. With the continuous development of industrial Internet, intelligent body will enter the vast industrial production field comprehensively, and combined with the Internet of Things, big data and other technologies, robots will take on more work responsibilities in the future.

2、Education field

The adoption of artificial intelligence technology in the field of education is currently a relatively obvious trend. Through artificial intelligence technology can solve many of the problems faced by traditional education, such as the amount of knowledge acquisition, teaching according to the material, assisted learning and other issues. With the continuous development of artificial intelligence technology, future educational robots will gradually enter the classroom and family.

3、Living service field

The field of life services covers more content. With the continuous development of Internet of Things technology, a large number of intelligent bodies will come into the home in the future in the field of smart home to create a more comfortable living environment for people. Smart body will provide different services according to the needs of different scenes, such as cleaning services, security services and other content.

In addition to the above areas, the future of intelligent body in the financial, medical, government and other fields will also have a wide range of applications, for the majority of the workplace, the future will need frequent communication and cooperation with a variety of intelligent body, from this point of view, it is necessary to learn a certain amount of artificial intelligence knowledge.

Advantages of robots

1. Robots reduce workplace injuries

Manufacturing has many processes that pose risks to humans. Tasks such as heavy lifting can cause physical injury to employees. Employees are also at risk of falling from heights. Other processes (such as welding) require high temperatures that human beings cannot handle.

Program a single arm to accurately handle all manufacturing processes. A robotic machine can efficiently lift, weld, paint and transport products from one point to another.

2. Reduce production costs

The robot moves from one job to another, thus reducing production time. The use of robots also reduces the cost of wages, insurance and benefits paid to workers.

3. Reduce production time

They say time is money. Robots reduce production time, which reduces production costs.

Robots never take a break and can work 24/7. When you hire robots to perform tasks in your manufacturing plant, you can save a lot of time and thus save on overall production costs.

4. Increase productivity and growth

The robots can work automatically and continuously, which increases production. Robots never ask for vacation or leave. Robots also never get sick or injured. They also never get tired. Therefore, they work non-stop.

Manufacturing industries that use general-purpose robotic arms register production, thereby replacing their production targets. These industries grow over time.

5. Take a position as a skilled worker

One of the headaches in manufacturing is the need for skilled labor.

A lack of qualified personnel can cause entire production departments to come to a halt. Robots can be used to fill the positions of skilled workers. Robotic machines work more accurately than humans, which increases production.

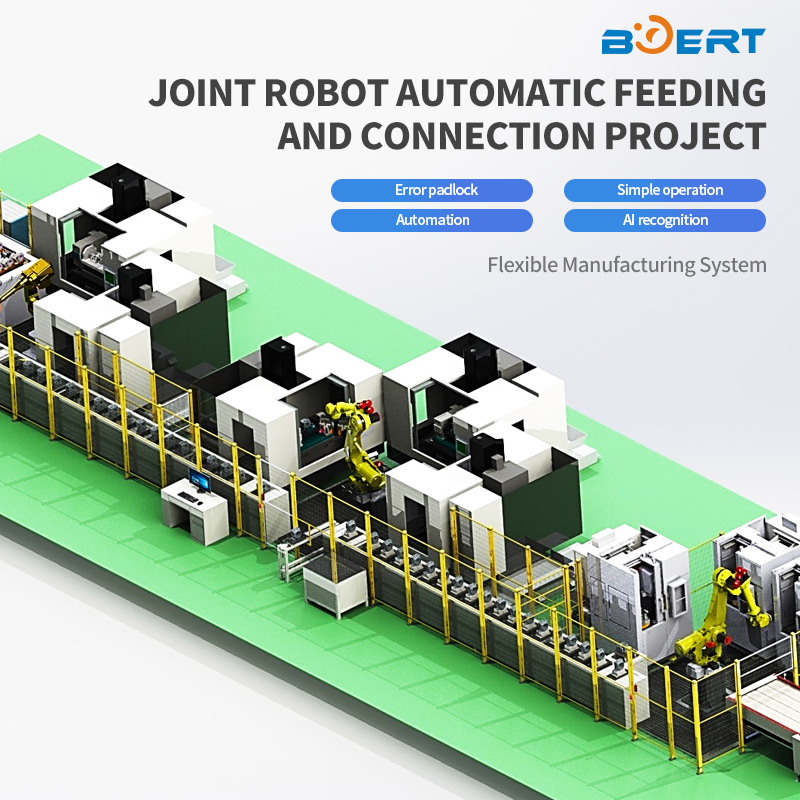

Sichuan Boert Robot Technology Co., Ltd. is the key investment and introduction enterprise of Luzhou high-tech intelligent manufacturing industry in 2016. We are committed to "intelligent manufacturing", and continue to summarize and explore the application of a variety of industries and standard equipment, to provide a full range of intelligent solutions for manufacturing customers. Our company in the field of automation production line equipment development covers robot system integration, robot vision integration application, automatic detection and intelligent three-dimensional warehouse, etc., and can provide technical training as well as after-sales service.Boert sticks to the service first philosophy. Whether it's a single device or a full set of turnkey projects, through our professional services and technical support, you will share our experience in different applications in different areas.

Contact Person:Bob Chen

Email:allenbell674@gmail.com Bobchen@scboert.com