The twin-screw extruder adopts modular barrel and parallel meshing twin-screw structure with simultaneous rotation. The screw elements can be recombined according to the material characteristics to achieve the mixing of materials with different characteristics and improve the mixing and blending effect. It is mainly used for filling, blending, modification, reinforcement, chlorination, polypropylene and highly absorbent resin processing of rubber, plastic and engineering resins. The following desktop twin-screw extruder manufacturers share the application advantages and selection criteria of desktop twin-screw extruders.

Twin-screw extruder consists of several parts such as transmission unit, charging unit, barrel and screw, etc. The effect of each part is similar to that of single-screw extruder. The difference from the single-screw extruder is that the twin-screw extruder has two parallel screws in a barrel with an "∞" cross section. The twin-screw extruder has active transport and self-cleaning functions, so its conveying capacity and material residual effect are better than the single-screw extruder. At the same time, the twin-screw extruder has a stronger shearing and stretching ability, so its dispersing and mixing ability is also stronger.

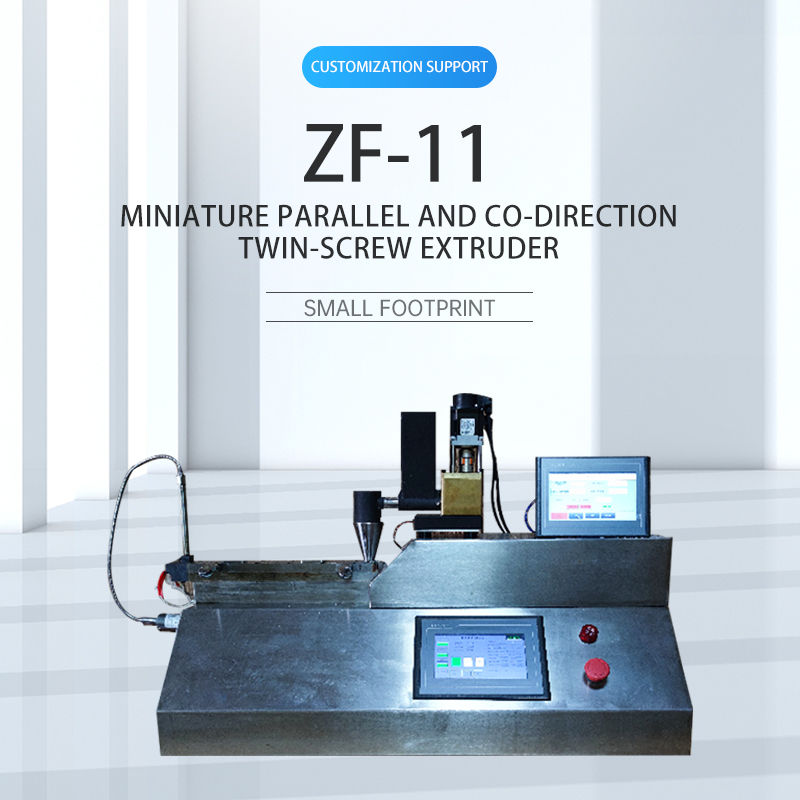

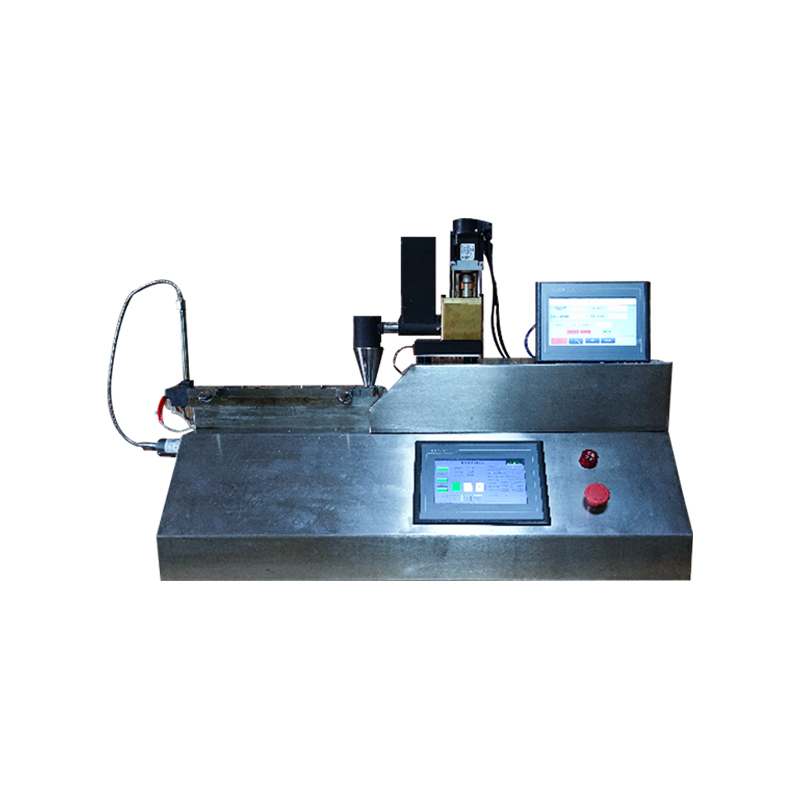

Twin-screw hot-melt extruder ZF-11 is the second generation of our product.

1. Its structure is more compact single shaft torque carrying capacity is stronger, a smaller size to transmit the same torque.

2. Short average material retention time and narrow range of residence time distribution.

3. The minimum feeding volume is reduced from 30g to 20g in the first generation product, which brings more than 30% material utilization efficiency or 30% cost reduction with less material consumption.

4. Fully scalable to stand-alone polymer modification/pharmaceutical mixing systems and continuous production lines, with simultaneous access to process formulations and related experimental data. Small-scale production is also possible, bringing great convenience to research and production.

5. Complete micro-compounding extrusion solutions are available with a wide range of accessories for 11mm twin-screw extruders.

Chengdu Zhufeng Lisi Technology Co., Ltd. was founded on May 15, 2019 and is located at 888 South Tianfu Avenue, Huayang Street, Tianfu New District, Chengdu, Sichuan Province. The main business is: micro co-mingled extrusion sets of equipment and drug hot melt extrusion process equipment development and manufacturing. At present, we have designed and developed a series of miniature desktop twin-screw extruders ZF11--ZF12 independently and successfully launched. We provide experimental platform for domestic enterprises, universities and research institutes, and reduce the feasibility verification and equipment procurement cost. We also conduct process research on drug and polymer compounding based on existing equipment. About equipment opportunities: imported equipment is expensive, equipment localization demand is clear; equipment advantages: industry has a benchmark product in the short term to take the follow strategy, play the latecomer advantage; domestic just started existing manufacturers without core technology (core components materials and pinion box). The company has a professional technical research and development team composed of highly educated personnel, and has applied for a number of exclusive technologies. We always adhere to the core values of "scientific and technological innovation, cooperation and win-win", timely solve all kinds of difficult problems of customers, so that customers can rest assured that no worries. Here, we warmly welcome people from all walks of life to visit our company and discuss cooperation! Welcome customers to call and consult!

Wang Xiaofei

womenhenqiang2009@163.com