Mold is called the "mother of industry", is the processing of raw materials, giving them a complete configuration and accurate size of processing tools, mainly used for efficient, mass production of industrial products in the relevant parts.

With the development of modern industry, molds have been widely used in automobiles, home appliances, consumer electronics, instruments, aerospace and medical devices and other products, of which about 60%-80% of the components need to rely on mold processing molding.

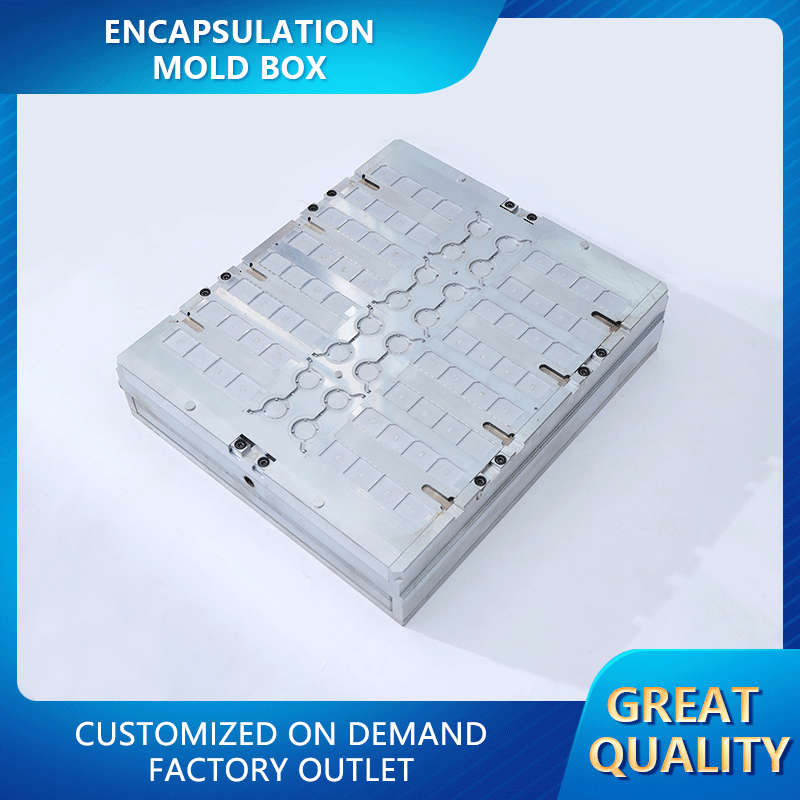

Packaging mold has played an irreplaceable role in our life, most of our daily necessities can not be separated from the packaging mold, such as computers, telephones, fax machines, keyboards, cups, chairs, spoons, auto parts and so on these plastic and hardware products. In addition, like cars, motorcycles engine external is also made out of encapsulation mold, light a car bumper, lights, in the net, plastic parts, interior parts and so on encapsulation mold should be used more than 20,000.

The role of Packaging molds

1.high degree of automation, simple operation. In the operation of the use of the mold can be found, the production and processing of the degree of automation, in the overall operation process is very simple, and many of the advantages of the mold in the production process is also very obvious.

2.Effectively improve production efficiency. Encapsulation mold itself in the use of the time can effectively improve production efficiency.

3.Reduce production costs. With a professional encapsulation mold, many products can be processed quickly, and these can better reduce production costs.

4.To ensure the safety of production. Safety production is an important element that every enterprise attaches importance to, and the overall safety of the encapsulation mold is also very high, the company can customize products according to specific needs, pay attention to product quality, to ensure that the mold can be better used.

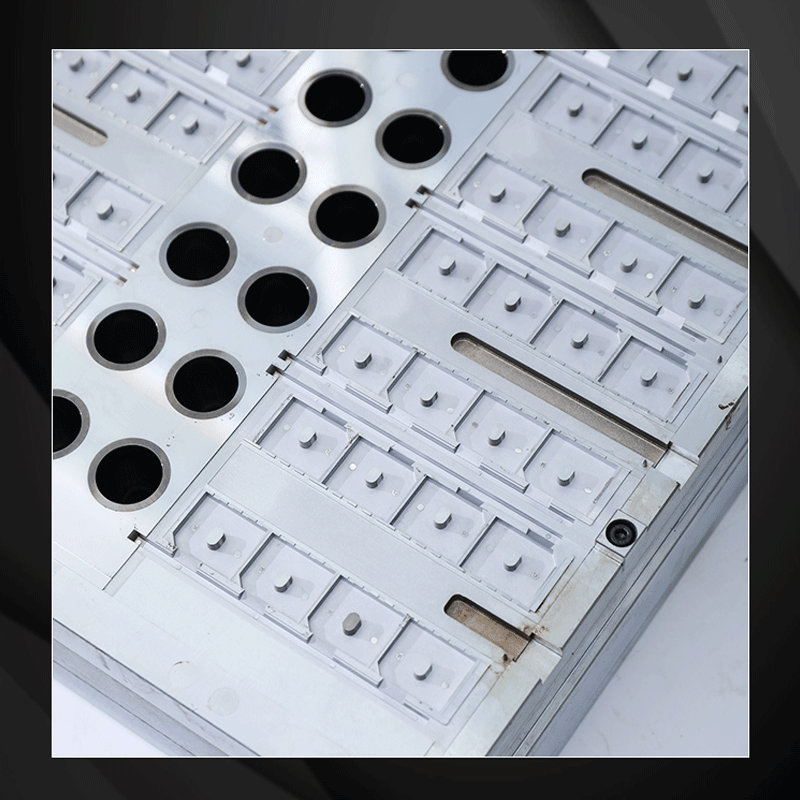

5.Professional manufacturers of mold design more reasonable. Professional manufacturers need to confirm the processing drawings before production and processing, semiconductor mold processing itself on the technical data requirements are very high, can meet more market demand.

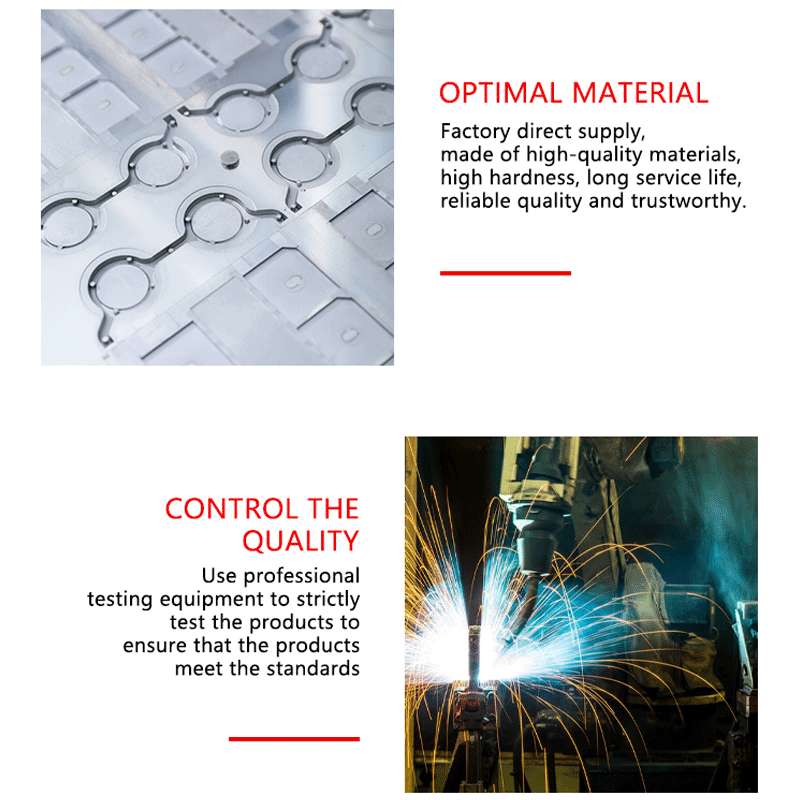

Sichuan Sijia Technology Co., Ltd. was established in August 2017. It is a comprehensive service company specializing in the research, development, design, manufacturing and sales of IC semiconductor packaging molds, cutting and punching molds, semiconductor automatic equipment, precision electronic machinery parts and other products, as well as technical consulting and technical services in related fields, and has independent import and export management rights for science, industry and trade. It is the first rectifier device factory in the west to introduce the latest production equipment and processes in the world today, and promote the development of the semiconductor industry in the western region with high-tech products.

Corporate Purpose:

To customers: win-win cooperation and common growth;

To shareholders: highly responsible and long-term return;

To society: responsibilities and obligations to give back to the public;

Treating employees: learning and training, self-accomplishment;

Enterprise Mission: Four Best in One Hundred Years; Strengthen Chinese Manufacturing Industry and Promote Chinese Mould and Mould Industry; Provide Excellent Quality Products and Promote Fine Product Concept; Promote Quality Service for Customers' Products; Build a Realization Platform for Employees' Life Value.

We have adopted the international advanced CAD/CAM/CAE computer aided design and analysis software, which can quickly analyze the product forming process, predict the form and location of product defects, and take measures during design to avoid product defects and ensure the scientificity, reliability and economy of the design.

Zou Lihua

yyl20221104@163.com