Test items and steps of smoke exhaust and fire damper products:

Fire dampers are widely used in various industries, but smoke and fire dampers are the most widely used in daily life. Smoke exhaust fire damper can automatically reduce fire during fire. In fact, the fire prevention effect of smoke damper is closely related to its quality. According to the knowledge of the fire damper manufacturer, the smoke exhaust fire damper needs to pass various tests to test its performance when leaving the factory. If the smoke exhaust fire damper can be closed freely during a fire, it means that the product can be put into use normally.

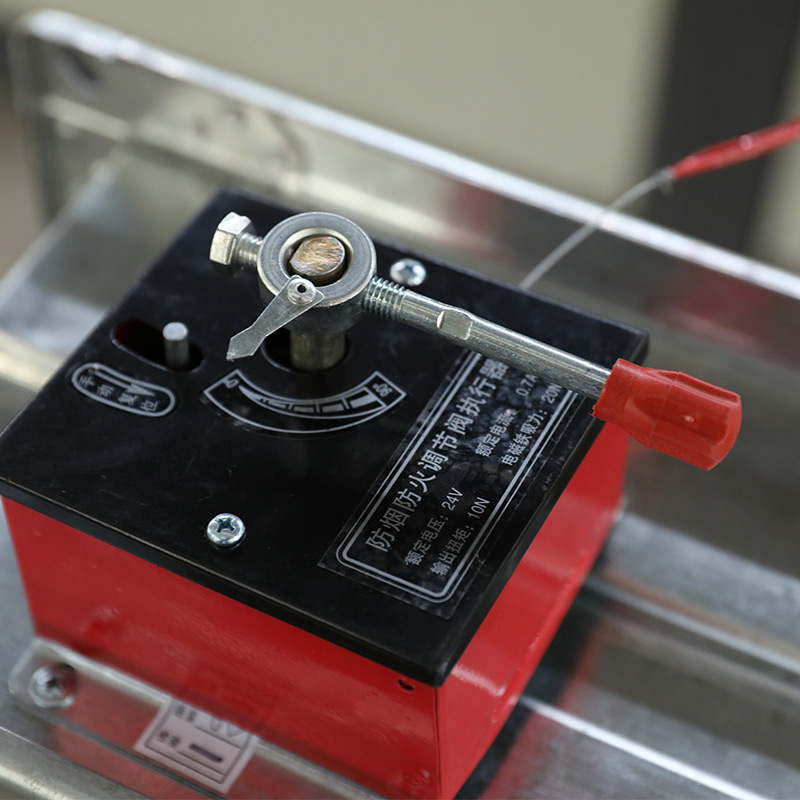

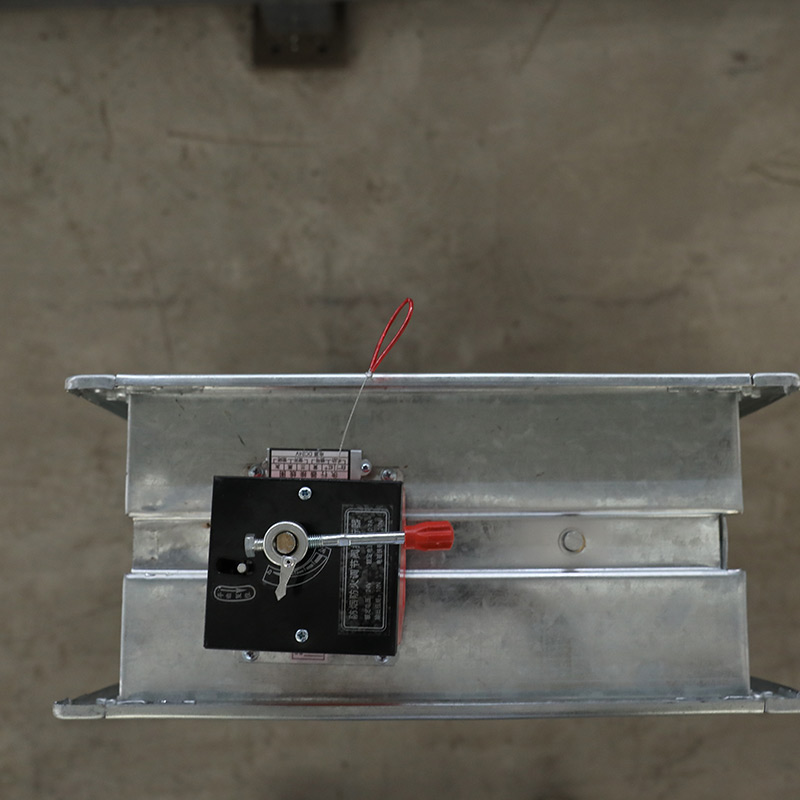

1. The manual operation of smoke exhaust fire damper shall be convenient, flexible and reliable.

2. The operating force for manual opening shall not be greater than 100N.

3. The smoke exhaust valve with electric operation performance shall be opened flexibly and reliably when it is 15% lower or 10% higher than the rated working voltage.

4. Open signal output function Open signal output function Smoke exhaust damper shall have open signal output function.

There are two inspection items for smoke exhaust fire damper products: closing reliability. During 10 closing operations, the fire damper shall be able to be flexibly and reliably closed from the position of opening and closing operations, and all parts shall be free of obvious deformation, wear and other damages affecting its sealing performance.

Turn off the reliability in case of fire, and fuse the fire damper temperature sensor with alcohol lamp or other fire sources; After the temperature sensor acts, the fire damper shall be closed automatically and reliably, including the automatic closing of smoke fire damper and smoke fire damper; The gap between blades or between blades and baffles shall not be greater than 2mm. Use a feeler gauge to measure the gap between blades or between blades and baffles. Opening reliability After 10 opening tests, both electrically and manually operated smoke exhaust valves will be opened immediately.

Purpose:

1. It is normally open. In case of fire, it will be closed when the flue gas temperature in the smoke exhaust pipe reaches 280 ° C, and meet the requirements of smoke leakage and fire resistance integrity within a certain period of time, so as to play the role of smoke separation and fire resistance.

2. The valve can be closed by DC24V power supply (electric smoke and fire damper).

3. Manual shutdown or manual reset.

4. After closing, DC24V electric reset (fully automatic smoke and fire damper, applicable to places where it is not convenient for people to operate).

5. The output valve closing signal can be interlocked with other fire protection equipment.

Advantage:

1. Low air leakage and good air tightness;

2. Electric starting consumes little current;

3. Strong corrosion resistance and long service life (stainless steel);

4. The actuator shall be driven flexibly, and the feedback and interlocking signals shall be accurate.

Luzhou Zhicheng Ventilation Equipment Co., Ltd. was established on May 16, 2018. Its registered office is located at No. 154, Yimen Sanjie, Shidong Town, Longmatan District, Luzhou City, Sichuan Province. Its legal representative is Wang Zhicheng. The business scope includes production and sales: ventilation ducts, fans, ventilation equipment; cock manufacturing; installation: refrigeration equipment, HVAC equipment, ventilation equipment, mechanical and electrical equipment, air conditioning, mechanical equipment, and fire fighting equipment. (Projects subject to approval according to law can only carry out business activities after being approved by relevant departments)

Zhicheng Wang

1823521066@qq.com