Description of the working principle of the solar street lamp: under the control of the intelligent controller in the daytime, the solar cell panel absorbs the solar light and converts it into electric energy through the sunlight, the solar cell module charges the battery pack in the daytime, and the battery pack supplies power to the LED light source at night to achieve the lighting function. The DC controller can ensure that the battery pack will not be damaged due to overcharge or overdischarge, and has the functions of light control, time control, temperature compensation, lightning protection, reverse polarity protection, etc.

There is no need to lay underground cables for solar street lamps and pay for lighting electricity. The key components of solar garden lamps, such as solar panel, solar DC street lamp intelligent controller, maintenance free battery, and lighting lamps, have been certified by the National Development and Reform Commission/GEF/World Bank as photovoltaic products. It is mainly applicable to the lighting of urban roads, community squares, industrial parks, tourist attractions, parks and green belts.

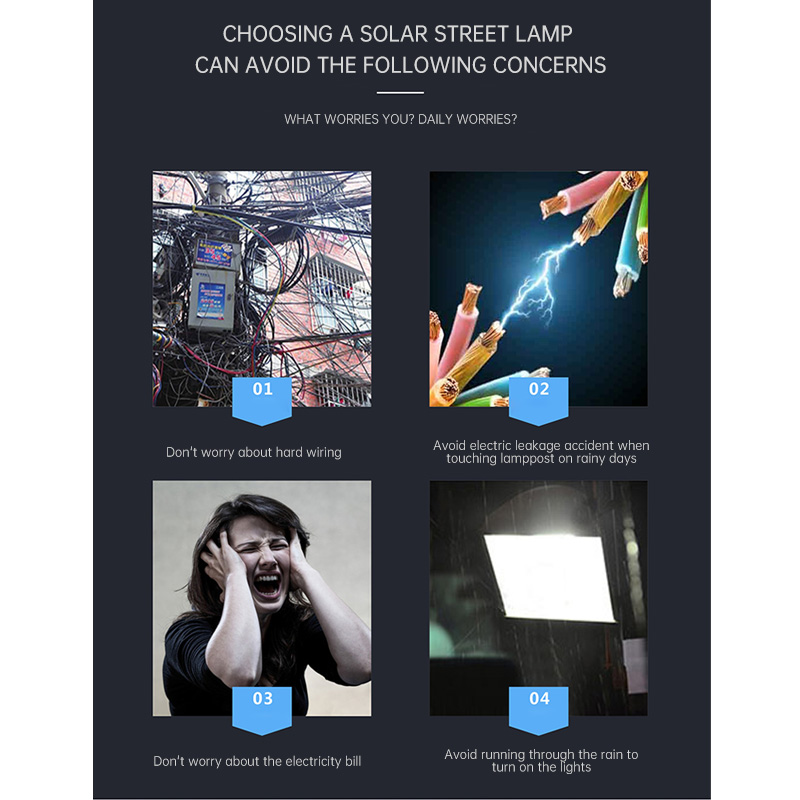

Solar energy is an inexhaustible, clean, pollution-free and renewable green energy. Solar power generation has incomparable advantages over other conventional energy sources, such as cleanness, high security, relative universality and sufficiency of energy, long life and maintenance free. Photovoltaic energy is considered to be the most important new energy in the 21st century. Solar street lamps do not need to lay cables, AC power supply and electricity charges; DC power supply and control; The utility model has the advantages of good stability, long service life, high luminous efficiency, simple installation and maintenance, high safety performance, energy conservation, environmental protection, economy and practicality.

It can be widely used in urban main and secondary roads, residential areas, factories, tourist attractions, parking lots and other places. Product parts Lamp pole structure: steel lamp pole and bracket, with plastic sprayed surface, and special anti-theft stainless steel screws are used for battery panel connection

Description of the working principle of the solar street lamp: under the control of the intelligent controller in the daytime, the solar cell panel absorbs the solar light and converts it into electric energy through the sunlight, the solar cell module charges the battery pack in the daytime, and the battery pack supplies power to the LED light source at night to achieve the lighting function. The DC controller can ensure that the battery pack will not be damaged due to overcharge or overdischarge, and has the functions of light control, time control, temperature compensation, lightning protection, reverse polarity protection, etc.

There is no need to lay underground cables for solar street lamps and pay for lighting electricity. The key components of solar garden lamps, such as solar panel, solar DC street lamp intelligent controller, maintenance free battery, and lighting lamps, have been certified by the National Development and Reform Commission/GEF/World Bank as photovoltaic products. It is mainly applicable to the lighting of urban roads, community squares, industrial parks, tourist attractions, parks and green belts.

Chongqing Yudai Road Industrial Technology Co., Ltd. was established in July 2016. Mainly engaged in hot-dip galvanizing of metal materials, spraying surface treatment, processing and manufacturing of steel structure products, etc. The company currently has a production workshop of 20,000 square meters, with advanced equipment such as CNC flame cutting machines, shearing machines, and angle steel production lines. The company has newly built two hot-dip galvanizing production lines, with an annual galvanizing production capacity of 200,000 tons and a 15.4-meter-long galvanizing pot, which can meet the needs of most customers. Two steel structure processing production lines have been built and put into operation, one is an ordinary steel structure processing production line, which mainly produces various lattice-type steel columns, three-pipe towers, pipe beams, columns, and suspenders for communication, electric power, and railways, and can also process communication towers. , outdoor lighting poles, sign poles, steel structure workshops; another special production line can produce buckle-type scaffolding, highway anti-collision brackets and other products, forming a production capacity of steel structure processing with an annual output of more than 30,000 tons.

Yongdan Shi

417126511@qq.com