Application of thermally conductive silicone film:With the popularity of chips and lithium battery application scenarios, heat dissipation has become an important bottleneck limiting product performance. Thermally conductive silicone gasket is widely used in security

LED industry use

Thermally conductive silicone film is used between aluminum substrate and heat sink

Power supply industry

Used with MOS tube, transformer (or capacitor/PFC inductor) and heat sink or shell between the thermal conductivity

Communication industry

TD-CDMA products in the motherboard IC and heat sink or between the shell of the thermal conductivity of heat dissipation

Set-top box DC-DC thermal conductivity between the IC and the housing

Applications in the automotive electronics industry

Automotive electronics industry applications (such as xenon lamp ballast, audio, car series products, etc.) can be used to thermal conductive silicone film

PDP / LED TV applications

Thermal conductivity between power amplifier IC, image decoder IC and heat sink (housing)

Home appliance industry

Microwave ovens / air conditioners (between fan motor power IC and housing) / induction cookers (between thermistor and heat sink)

Product advantages

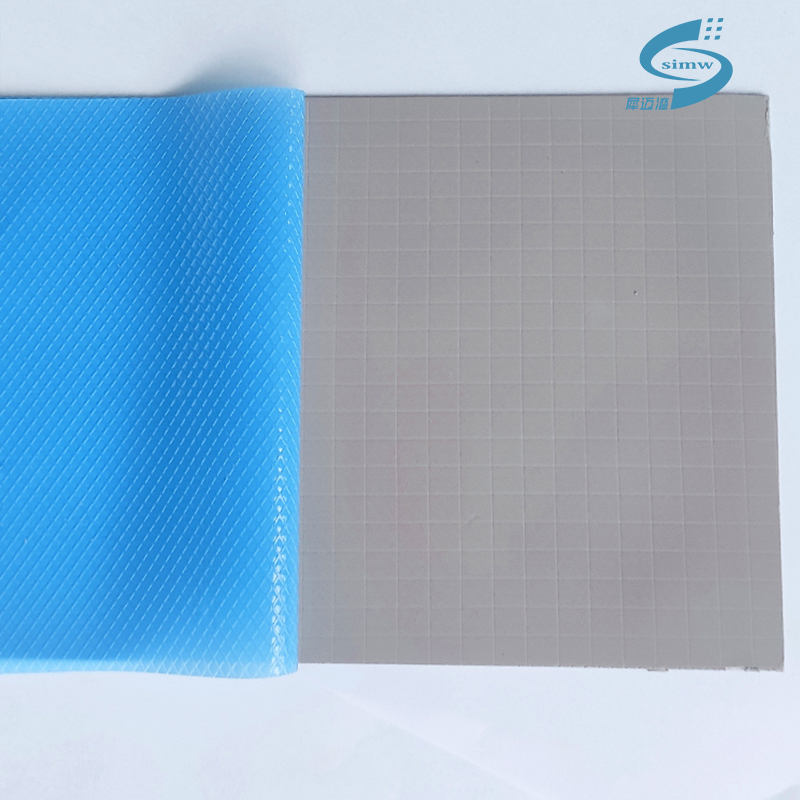

1.the material is soft, good compression performance, good thermal conductivity and insulation performance, the adjustable range of thickness is relatively large, suitable for filling cavities, both sides have natural adhesion, operability and maintainability.

2.with the supplement of thermal conductive silicone film, can make the contact surface between the heat source and the heat sink better full contact, truly face-to-face contact. The response in temperature can reach as small a temperature difference as possible.

3.the thermal conductivity of the thermal conductive silicone film has adjustable thermal conductivity, and better thermal stability.

4.thermal conductive silicone film in the structure of the process of bridging the difference, reducing the heat sink and heat dissipation structural parts of the process of differential requirements.

5.thermal conductive silicone film with insulation properties.

6.The thermal conductive silicone film has the effect of vibration and sound absorption.

7.The thermal conductive silicone film has the convenience of installation, testing and reusability.

8.According to the different product models, the products have different functions.

9.the product is environmentally friendly, able to customize production and self-development, with EU CE certification, ISO certification, product testing reports, short delivery time.

Ximaiwan is a new material technology company integrating R&D, manufacturing and sales. For the chip, communications, security, home appliances, automotive, light sources, power supplies, construction, integrated circuits, weapons and equipment and other areas of demand for high-quality thermal management, to provide customers with industry-leading thermal management products and conduction, thermal storage, heat dissipation, temperature regulation, energy saving and other technical services. It is the largest and strongest thermal power R&D and production base of silica gel, gel and graphene thermal conductive plastic in southwest China. With advanced R&D and testing equipment, the company is in the leading position in the industry. The company has passed ISO9001, ISO14001, ISO45001 and other quality management system certification. Adhering to the concept of "quality first, customer-oriented", we provide more personalized support and services to become a professional solution center for thermal interface materials, and win-win cooperation and mutual growth with customers.

Junli Fu

348889136@qq.com