The automotive industry is in a stage of vigorous development. With the constant changes in customer needs, manufacturers are launching new products faster and faster. The continuous emergence of new projects and changes may lead to all kinds of problems in the quality of delivered products. If these quality problems cannot be traced and controlled in a timely and effective manner, it will bring serious consequences to the life and property safety of the end customers. This makes automobile manufacturers put forward higher requirements for the quality traceability of downstream automobile parts suppliers. Therefore, laser printers, laser marking machines, and small character inkjet printers play an important role in it.

The traditional product traceability of the auto parts industry has always been to track the product parts information, relying on the information identification of the accessories of each product, so that consumers or industry professionals can judge the understanding of quality responsibility. The advantage of this method is that there are employees who have many years of work experience can quickly find the relevant production information, parts supplier information, and part batch information of the faulty parts. If an auto parts manufacturing company wants to recall parts with quality defects, it must first trace the product information with quality defects and analyze the production process of the products. If an error is found in any production link, it must be traced back to all finished products in that link. In order to better solve the traceability problem of auto parts manufacturing products.

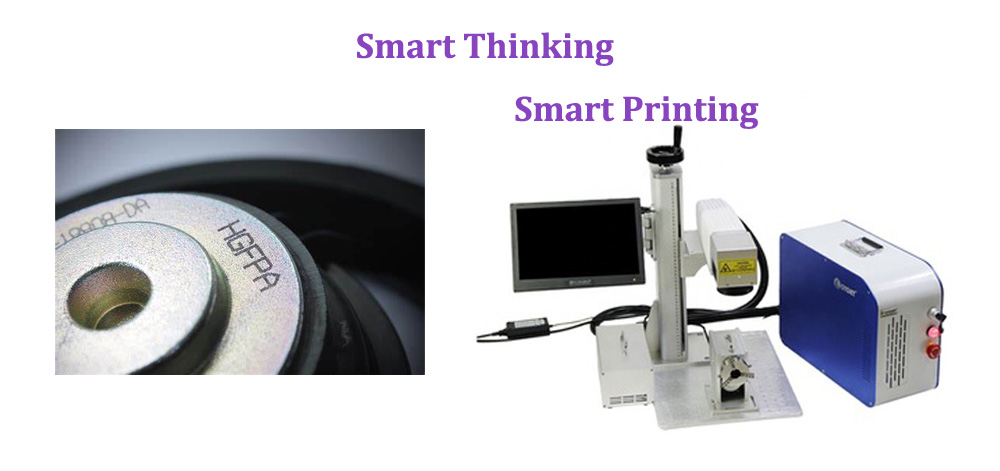

The main functions of the laser printer to assist in the traceability of the production history of auto parts:

The traceability of product sales and shipments can be traced back to the pallets, outer packaging boxes, and product packaging barcode labels issued by the shipment. Product packaging barcode label traceability, through the product packaging barcode label, trace back to the production order batch of the barcode label. Production order batch traceability, through the production order batch, various data of the production process can be traced, including:

1. What materials from which supplier and which batch are used for auto parts?

2. What time, by whom, on which machine, with which mold, and with what process parameters?

3. What processes, quality tests, repairs, inspections have gone through in the production process?

4. The auto parts manufacturing traceability system can improve customers' confidence in product quality.

In the automotive industry, the use of laser inkjet printers, inkjet printers, and marking machines to achieve a traceability system for auto parts manufacturing can play a very critical role. It will help to build a good brand image of the enterprise, improve the market competitiveness of auto parts products, and expand the market share of products. At the same time, it can also enhance the quality and safety awareness and self-responsibility of employees, and strengthen the standardized management of enterprises, and continuously promote the great improvement of the quality of auto parts products.

CYCJET is the brand name of Yuchang Industrial Company Limited. As a manufacturer, CYCJET have more than 16 years of experience for R& D different types of handheld inkjet printing solution, Laser printing solution, and portable marking solution, High Resolution Printing solution in Shanghai China.

Contact Person: David Guo

Telephone: +86-21-59970419 ext 8008

MOB:+86-139 1763 1707

Email: sales@cycjet.com

Keywords :

Small character inkjet printer

Working video: