working principle:

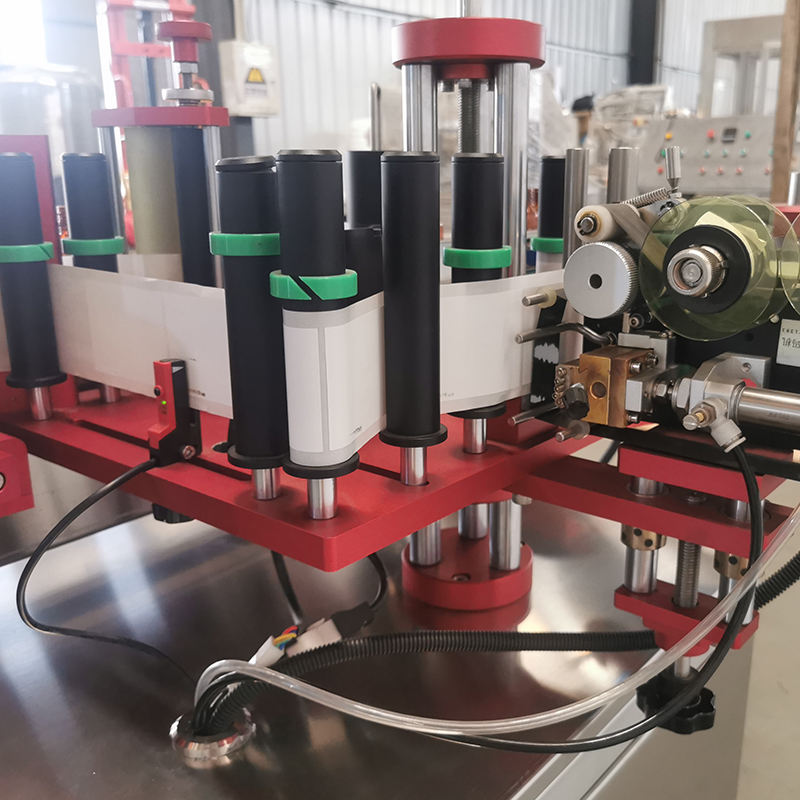

At the beginning of the working process, the case is fed to the labeling machine at a constant speed on the conveyor belt. The mechanical fixing device separates the boxes for a fixed distance, and pushes the boxes forward along the direction of the conveyor belt. The mechanical system of the labeling machine includes a driving wheel, a labeling wheel, and a reel. The drive wheel intermittently drags the label belt to move, and the label belt is pulled out of the reel. At the same time, the label belt will be pressed on the box by the label wheel. Open loop displacement control is adopted on the reel to maintain the tension of the label strip. Because the labels are closely connected with each other on the label strip, the label strip must be started and stopped continuously.

The label is attached to the box when the labeling wheel and the box move at the same speed. When the conveyor belt reaches a specific position, the drive wheel of the label belt will accelerate to the speed matching the conveyor belt, and then decelerate to stop after labeling.

As the label belt may slide, it has a registration mark on it to ensure that each label is correctly placed. The registration mark is read by a sensor. During the deceleration phase of the label belt, the driving wheel will be adjusted from the new position to correct any position error on the label belt.

Function introduction:

★ This machine is applicable to the self-adhesive labeling of round bottles

★ Adopt servo drive system and PLC program control;

★ The labeling is accurate and firm;

★ No bottle, no label, no label automatic detection;

★ It has the function of automatic counting and printing batch number and production date;

★ It can be connected with other equipment or used alone.

Main configuration:

① Made of 304 stainless steel

② Bid issuing agency, bottle separating agency and rolling agency (Chengdu Haotong)

③ Touch screen (Kunlun connected)

④ PLC (Taiwan Delta)

⑤ Frequency converter (common transmission)

⑥ Servo motor, servo drive system (Shenzhen R&C)

⑦ Conveying motor, bottle separating motor, paper rolling motor (Zhejiang Oubang)

⑧ Optical fiber sensor (Panasonic, Japan)

⑨ Calibration photoelectric (Panasonic, Japan)

⑩ Hot coding machine (Fujian Nanyun)

Technical parameters:

① Applicable bottle type: round bottle

② Labeling specification: as agreed

③ Label specification: 30-135mm high, 15-150mm long; Drum diameter: internal Φ 76mm, outer Φ 320mm

④ Power supply: 220V/50Hz

⑤ Power: 1.3kw

⑥ Production capacity: 30-45 bottles/minute

Chengdu Haotong Light Industrial Machinery Co., Ltd. was established in 2006. The company invested 30 million yuan, built a 5000 square meter standardized structure workshop, and has a series of automatic equipment such as automatic plasma welding, automatic laser cutting machine, automatic pipe welding machine, automatic tube sheet welding machine, automatic polishing machine, and digital control machine tools, As well as dozens of machines and tools for professional processing of stainless steel equipment, a set of liquid sandblasting facilities for professional surface treatment, and four sets of 5T crane cranes. It can produce and process professional equipment for pharmaceutical, food, chemical and other industries that meet the requirements of drug and food safety and health.

The company has more than 60 employees, including 15 engineering technicians, 30 professional technicians and more than 10 management personnel. The company has set up administrative department, sales department, packaging business department, technology department, supply department, production department, quality inspection department, finance department and other management organizations, and passed ISO9001 quality management system certification in June 2013. In 2018, the company obtained the safety production standardization certificate and the national environmental protection acceptance approval, which can adapt to the requirements of modern enterprise operation and have the competitiveness of the market economy.

Since its establishment, Chengdu Haotong Light Industrial Machinery Co., Ltd. has adhered to the principle of customer first, quality first, and service first. Starting from practice, it is committed to the research, development and application of food equipment, pharmaceutical equipment, chemical equipment, and production and sales of various stainless steel tank equipment, filling production line equipment, non-standard stainless steel products, etc. Non standard experts: "Tianfu Haotong", we will customize according to your actual needs to meet your production needs. We are willing to build a valuable industry brand with excellent equipment and quality service. "Tianfu Haotong" will go forward hand in hand with you to a new era!

Yin Qiao

965534387@qq.com